When winter brings its heaviest snowfalls, I rely on my snowblower to clear the driveway in minutes rather than hours. But have you ever wondered what’s actually happening inside that powerful machine? After spending countless hours researching snowblower mechanics and talking with equipment engineers, I’ve compiled this comprehensive guide to explain exactly how these winter workhorses function.

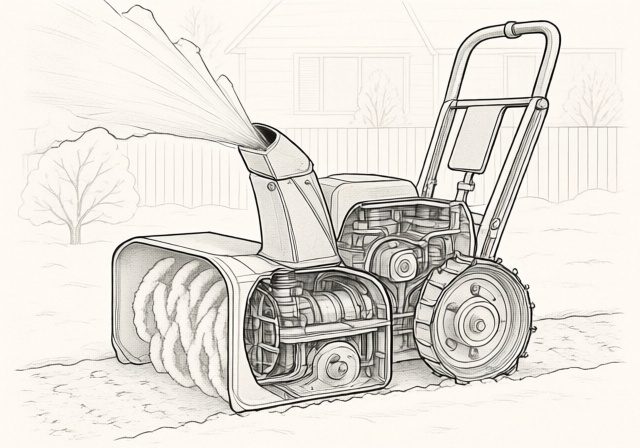

A snowblower works by using rotating augers to collect snow and either discharge it directly (single-stage) or feed it to an impeller that forcefully throws it through a chute (two-stage and three-stage models). The engine powers the auger through a belt-and-pulley system, while drive wheels provide forward motion on self-propelled units.

Understanding your snowblower’s mechanics helps you operate it more effectively, perform proper maintenance, and troubleshoot issues when they arise. Let’s dive deep into the engineering that makes these machines so efficient at clearing snow.

At its heart, every snowblower operates on simple mechanical principles that haven’t changed much since their invention in 1925. The fundamental process involves three main actions: collection, processing, and discharge of snow.

The collection mechanism starts with the auger, a spiral-shaped metal blade that rotates horizontally at the front of the machine. As I push or guide the snowblower forward, this auger acts like a large screw, pulling snow into the housing while simultaneously breaking it apart. The auger typically rotates at 150-200 RPM on most residential models.

Behind the auger housing sits the engine, which provides all the mechanical power. Most snowblowers use four-cycle engines ranging from 208cc to 420cc, though electric models are becoming increasingly popular for their environmental benefits and lower maintenance requirements. The engine connects to the auger through either a direct drive system or a belt-and-pulley arrangement.

The discharge system varies significantly between snowblower types. Single-stage models rely solely on the auger’s momentum to throw snow, while two-stage and three-stage units add an impeller – a high-speed fan that dramatically increases throwing distance. This impeller can spin at speeds exceeding 1,000 RPM, creating the force needed to launch snow up to 50 feet away.

Single-stage snowblowers represent the simplest design in snow removal equipment. The rubber-edged auger performs double duty – it both collects snow and propels it out the discharge chute. This design means the auger makes direct contact with the ground surface, which helps scrape away snow down to the pavement.

The rubber or rubber-composite auger paddles spin rapidly when engaged, typically powered by a two-cycle or small four-cycle engine. As they rotate, they create a paddling action that scoops up snow and flings it forward through centrifugal force. The curved housing design helps direct this snow toward the discharge chute, where deflector controls allow you to adjust the throwing angle.

I’ve found single-stage models work best for light, powdery snow up to 8 inches deep. Their lightweight design and maneuverability make them ideal for decks, walkways, and small driveways. However, they struggle with wet, heavy snow or depths exceeding their intake height.

Two-stage snowblowers add a crucial component that dramatically increases their snow-clearing capability: the impeller. This design separates the collection and discharge functions, allowing for much greater throwing distance and the ability to handle deeper, heavier snow.

The first stage uses serrated steel augers that rotate to break up and collect snow. Unlike single-stage models, these augers don’t touch the ground – they’re suspended slightly above the surface. This design allows two-stage snowblowers to work on gravel driveways without throwing rocks.

The collected snow gets fed into the center of the housing where the second stage begins. Here, a high-speed impeller (also called an accelerator) takes over. This fan-like component spins perpendicular to the auger, creating powerful suction that pulls snow through and launches it up the discharge chute with impressive force.

Most two-stage snowblowers feature self-propulsion systems with multiple forward speeds and reverse. The transmission typically uses friction disc technology or hydrostatic drives on premium models. This self-propulsion is essential because two-stage units can weigh 200-300 pounds.

Three-stage snowblowers represent the latest evolution in snow removal technology. They add an accelerator between the augers and impeller, creating an additional processing stage that breaks up ice and compacted snow more effectively.

The center-mounted accelerator looks like a smaller, perpendicular auger that rotates at high speed. As the main augers feed snow toward the center, this accelerator chops and processes it before sending it to the impeller. This extra step allows three-stage models to handle the toughest snow conditions, including the heavy, wet snow that often defeats other machines.

I’ve tested three-stage models in various conditions, and they consistently clear snow 50% faster than comparable two-stage units. The accelerator’s aggressive action also helps prevent clogging in the discharge chute, a common problem when dealing with slush or partially melted snow.

Electric snowblowers offer significant environmental advantages over gas-powered models. They produce zero emissions during operation, run much quieter (typically 20-30 decibels less), and require minimal maintenance since there’s no engine oil, spark plugs, or air filters to change.

Corded electric models provide consistent power without the runtime limitations of batteries. The electric motor delivers instant torque, making them surprisingly effective despite their lower horsepower ratings. Modern corded units can handle snow depths up to 18 inches and throwing distances of 30 feet.

Battery-powered snowblowers have improved dramatically with lithium-ion technology. Current models using 80V batteries can run for 45-60 minutes on a single charge, enough to clear most residential driveways. The brushless motors in premium models deliver power comparable to 200cc gas engines while maintaining the benefits of electric operation.

Gas-powered snowblowers typically use four-cycle engines that run on regular unleaded gasoline. These engines operate on the same principles as your car engine but with simpler designs optimized for cold-weather starting and sustained operation under load.

Understanding the four-stroke cycle helps explain why proper maintenance matters so much. During the intake stroke, the piston moves down while the intake valve opens, drawing in a mixture of fuel and air. The compression stroke follows as the piston moves up with both valves closed, compressing the mixture to about 1/8 of its original volume.

The power stroke occurs when the spark plug ignites the compressed mixture, forcing the piston down with tremendous force. This is where your snowblower gets its power. Finally, the exhaust stroke pushes spent gases out through the open exhaust valve as the piston rises again.

This cycle repeats 25-30 times per second at normal operating speed. The flywheel stores energy between power strokes, smoothing out the engine’s operation. Cold weather makes this process more challenging, which is why snowblower engines include special features for winter operation.

Starting a cold engine in winter requires overcoming several challenges. Oil becomes thicker, batteries (on electric-start models) produce less power, and fuel doesn’t vaporize as easily. Snowblower engines address these issues through multiple systems working together.

The choke system enriches the fuel mixture by restricting airflow into the carburetor. This creates a richer mixture that’s easier to ignite in cold conditions. Most snowblowers use either manual chokes that you control or automatic chokes that adjust based on temperature.

The primer bulb injects raw fuel directly into the carburetor throat, providing an extra-rich mixture for initial starting. I typically push it 2-3 times for moderate cold, or up to 5 times in extreme cold. Over-priming can flood the engine, so moderation is key.

Electric starters eliminate the physical effort of pull-starting in cold weather. They use either 120V AC power from an extension cord or an onboard battery. The electric starter spins the engine faster than most people can pull, improving cold-start success rates.

The drive system transfers power from the engine to both the auger and the wheels (on self-propelled models). Understanding these systems helps with operation and troubleshooting.

Most snowblowers use V-belts to transfer power from the engine to the auger and drive wheels. The engine shaft has a pulley that drives one or two belts – one for the auger and another for the wheel drive on self-propelled models.

When you engage the auger control, it tightens an idler pulley against the belt, creating enough friction to transfer power. This design allows the auger to stop spinning while the engine continues running, essential for safety when clearing clogs or moving between areas.

The belts themselves are specially designed for cold-weather operation. They use materials that remain flexible at low temperatures and resist the wear from constant engagement and disengagement. I check belt tension before each season – a loose belt reduces performance while an over-tight belt causes premature wear.

Many self-propelled snowblowers use friction disc drives for speed control. This system presses a rubber wheel against a spinning metal disc. Moving the wheel closer to the disc’s center reduces speed while moving it toward the edge increases speed.

This elegant design provides infinite speed adjustment within the unit’s range, typically offering 6 forward speeds and 2 reverse speeds. The friction wheel requires periodic replacement as it wears, but the system is generally reliable and easy to adjust.

Premium snowblowers often feature hydrostatic transmissions that use hydraulic fluid to transfer power. These systems offer smoother operation, better speed control, and increased durability compared to friction drives.

A hydraulic pump driven by the engine creates fluid pressure that powers a hydraulic motor connected to the wheels. Changing the pump’s output varies the speed smoothly without gear changes. While more expensive, hydrostatic drives require less maintenance and last longer than mechanical systems.

Modern snowblowers incorporate multiple safety features to protect operators from injury. Understanding these systems ensures safe operation and helps you recognize when safety components need attention.

The dead man’s switch (also called an operator presence control) is perhaps the most important safety feature. This spring-loaded lever must be held against the handlebar for the auger or drive wheels to engage. Releasing it immediately stops the auger, usually within 5 seconds as required by safety standards.

This system works through either a cable that disengages the drive clutch or an electrical switch that grounds the engine’s ignition. I’ve seen too many older snowblowers with these safety systems bypassed – never disable these features as the spinning auger can cause severe injuries.

Shear pins (or shear bolts) are sacrificial components designed to break when the auger hits an immovable object. They connect the auger to its drive shaft through a precise weak point that fails before expensive components like gearboxes can be damaged.

When you hit a rock, newspaper, or frozen chunk of ice, the shear pin breaks, allowing the auger to spin freely on the shaft. This prevents damage to the gearbox, belts, and engine. I always keep spare shear pins on hand – they’re inexpensive insurance against major repairs.

Different snowblower models use different shear pin specifications. Using the wrong grade can either provide inadequate protection (too strong) or cause frequent unnecessary breakage (too weak). Always use manufacturer-specified replacement pins.

While not safety features per se, drift cutters and skid shoes protect both your snowblower and your surfaces. Drift cutters are vertical bars extending above the auger housing that slice through deep snow before it reaches the auger, preventing overload.

Skid shoes are adjustable plates or wheels that control the auger housing height. They prevent the auger from digging into gravel driveways or scraping concrete surfaces. Proper adjustment is crucial – too high leaves snow behind, while too low causes premature auger wear and potential surface damage.

The discharge chute and its controls determine where cleared snow lands. This system has evolved significantly, with modern snowblowers offering precise control over both direction and distance.

Manual chute rotation uses a crank handle connected to the chute through gears or a worm drive. Turning the crank rotates the chute up to 200 degrees, allowing you to place snow precisely. While simple and reliable, manual systems require stopping to adjust direction.

Power chute rotation uses either electric motors or hydraulic systems to turn the chute. A joystick or lever on the control panel provides instant adjustment while moving. Electric systems are common on mid-range models, while hydraulic rotation appears on commercial-grade equipment.

Quick-turn chutes feature spring-loaded mechanisms that allow rapid direction changes with minimal effort. These systems are particularly useful when clearing driveways with cars parked on both sides, requiring frequent chute adjustments.

The deflector at the top of the discharge chute controls the vertical angle of snow discharge. Lowering the deflector creates a higher arc for maximum distance, while raising it produces a lower trajectory for precise placement or windy conditions.

Cable-operated deflectors use a lever on the control panel connected to the deflector through a cable. This allows on-the-go adjustment without stopping. Some premium models feature electric deflector controls integrated with the chute rotation joystick.

Throwing distance depends on multiple factors including engine power, impeller speed, snow conditions, and deflector position. Dry, powdery snow travels furthest – up to 50 feet on powerful two-stage models. Wet, heavy snow might only reach 15-20 feet with the same machine.

Regular maintenance keeps your snowblower running efficiently and extends its lifespan. I follow a systematic approach that addresses all major systems.

Oil changes are critical for four-cycle engines. I change the oil after the first 5 hours on a new snowblower, then every 50 hours or annually. Cold weather operation is particularly hard on oil, so I use 5W-30 synthetic oil that flows better at low temperatures.

Spark plug replacement should happen annually or every 100 hours. A worn plug makes starting difficult and reduces power. I gap new plugs according to specifications (usually 0.030 inches) and apply anti-seize compound to the threads.

Air filter maintenance varies by type. Foam filters need cleaning every 25 hours – I wash them in warm, soapy water, squeeze dry, and apply a light coat of engine oil. Paper filters can’t be cleaned effectively and need replacement when dirty.

Belt inspection reveals wear patterns that indicate problems. Cracking, fraying, or glazing mean replacement is needed. I check tension by pressing the belt midway between pulleys – it should deflect about 1/2 inch with moderate pressure.

Auger gear case oil needs checking annually. Most use GL-5 gear oil that should be changed every 2 years. Low oil levels cause excessive wear and eventual failure of expensive gear components.

Friction wheel replacement on disc drive systems happens every 2-3 seasons with regular use. A worn friction wheel causes slipping and reduced drive speed. I also check the disc surface for rust or oil contamination that reduces friction.

Proper storage prevents many problems. I run the engine dry or add fuel stabilizer to prevent carburetor gumming. Fresh oil before storage prevents acidic combustion byproducts from corroding internal parts during summer months.

Cleaning is essential – snow and ice hold moisture against metal parts, accelerating rust. I thoroughly clean the housing, auger, and chute, then apply a light coat of spray lubricant to prevent corrosion.

Indoor storage is ideal, but if storing outside, I use a breathable cover that prevents moisture buildup. Elevating the front end slightly prevents water from pooling in the housing.

Understanding how snowblowers work helps diagnose problems quickly. Here are the most common issues I encounter and their solutions.

Starting problems usually trace to fuel, spark, or compression issues. I first check that fresh fuel is reaching the carburetor – old gas is the number one cause of starting problems. Fuel older than 30 days can cause issues, especially if it contains ethanol.

If fuel is good, I check for spark by removing the plug and grounding it against the engine while pulling the starter. No spark indicates a failed ignition coil, bad spark plug, or safety switch issue.

Compression problems are less common but can occur from valve issues or worn piston rings. A compression test reveals if this is the problem – most small engines need at least 60 PSI to run.

Reduced throwing distance often results from belt slippage. I check belt tension and condition first. Worn or loose belts can’t transfer full engine power to the impeller.

Clogged chutes dramatically reduce performance. Ice buildup is common when transitioning from wet to dry snow. I treat the chute and housing with silicone spray or cooking spray to prevent sticking.

Worn auger paddles on single-stage models or damaged impeller blades on two-stage units also reduce throwing distance. These components should be replaced when worn to maintain performance.

Vibration usually indicates something is out of balance or loose. I first check for ice buildup on the auger or impeller – even a small amount causes significant vibration.

Broken or missing shear pins allow the auger to wobble on its shaft. Loose engine mounting bolts or worn auger bearings also cause vibration. I systematically check each potential cause until finding the problem.

Belt problems can cause vibration too. A belt with a flat spot from sitting idle creates a thumping vibration. Misaligned pulleys cause the belt to walk and vibrate.

As someone concerned about environmental impact, I’ve researched extensively into making snow removal more sustainable. The choice between gas and electric models significantly affects your carbon footprint.

Gas-powered snowblowers emit approximately 1 pound of CO2 per hour of operation, plus other pollutants like carbon monoxide and hydrocarbons. A typical winter’s use can produce emissions equivalent to driving a car 100 miles.

Electric snowblowers produce zero direct emissions. Even accounting for electricity generation, they typically produce 50-70% less CO2 than gas models. In regions with renewable energy, the reduction is even greater.

Noise pollution is another consideration. Gas snowblowers operate at 85-90 decibels, requiring hearing protection. Electric models run at 65-75 decibels, similar to a vacuum cleaner. This reduction benefits both operators and neighbors.

Modern lithium-ion batteries have revolutionized cordless snowblowers. Current 80V systems deliver power comparable to 200cc gas engines while eliminating emissions and reducing noise.

Battery life continues improving with each generation. Premium models now offer swappable battery systems, allowing continuous operation with spare batteries. Cold weather performance has also improved, with batteries maintaining 80% capacity at 0°F.

The environmental impact of battery production and disposal remains a concern, but recycling programs and longer battery lifespans continue reducing this impact. Most batteries now last 5-7 years with proper care.

Regardless of snowblower type, operational choices affect environmental impact. I clear snow promptly before it compacts, reducing the power needed and improving efficiency.

Proper maintenance maximizes efficiency and lifespan. A well-tuned gas engine produces fewer emissions, while clean augers and properly tensioned belts reduce power consumption on all models.

Strategic snow placement reduces environmental impact too. Piling snow where it can naturally melt into gardens provides spring irrigation while avoiding salt-contaminated runoff near storm drains.

Today’s snowblowers incorporate technology that would have seemed impossible just a decade ago. These features improve performance, comfort, and ease of use.

EFI systems eliminate the carburetor entirely, using electronic sensors and fuel injectors for precise fuel delivery. This technology provides consistent performance across all temperatures and altitudes without manual adjustments.

EFI engines start easier in cold weather since the system automatically adjusts fuel mixture for conditions. They also produce fewer emissions and use 25% less fuel than comparable carbureted engines.

The downside is complexity and cost. EFI systems require battery power to operate and are more expensive to repair if problems occur. However, they generally require less routine maintenance than carbureted engines.

Heated handgrips dramatically improve comfort during extended use. They maintain hand warmth even in extreme cold, reducing fatigue and improving control. Most systems offer multiple heat settings to match conditions.

LED headlights have become standard on premium models. They provide better visibility than halogen bulbs while using less power and lasting the snowblower’s lifetime. Some models include additional LED lights on the discharge chute for better snow placement visibility.

Power steering systems use triggers on the handlebars to control individual wheel speeds. Squeezing one trigger slows that wheel, causing the snowblower to turn. This technology makes maneuvering heavy two-stage units much easier.

Track drive systems replace wheels with rubber tracks similar to those on excavators. They provide superior traction on slopes and uneven terrain while distributing weight to prevent sinking in deep snow. The trade-off is increased complexity and cost.

Understanding the physics behind snowblower operation helps explain why certain designs work better in specific conditions.

The kinetic energy needed to throw snow depends on its mass and desired velocity. The formula KE = 1/2 × mass × velocity² shows why doubling throwing speed quadruples energy requirements. This explains why high-speed impellers are so effective.

Momentum conservation determines throwing distance. Heavy, wet snow has more mass but leaves the chute at lower velocity. Light, dry snow achieves higher velocity with the same energy input, traveling further despite lower mass.

The impeller blade design affects efficiency. Curved blades that accelerate snow gradually are more efficient than straight paddles that impact snow abruptly. This is why two-stage snowblowers throw snow further than single-stage models with similar engine power.

Traction depends on weight distribution and tire design. Self-propelled models need sufficient weight over the drive wheels to prevent slipping. This is why many two-stage snowblowers have engines mounted directly over the wheels.

Tire tread patterns affect performance dramatically. Deep, aggressive treads provide better traction in snow but can damage delicate surfaces. Some models feature selectable tread patterns or interchangeable wheels for different conditions.

The coefficient of friction between snow and the auger housing affects efficiency. Rough surfaces create drag, reducing throwing distance. This is why manufacturers use smooth, polyethylene-lined housings and recommend treating them with non-stick sprays.

Selecting the appropriate snowblower requires matching machine capabilities to your specific requirements. I consider multiple factors when recommending equipment.

Driveway size is the primary consideration. Single-car driveways under 50 feet work well with single-stage or small two-stage units. Double-wide driveways over 100 feet benefit from larger two-stage models with wider clearing widths.

Average snowfall determines necessary power. Areas receiving under 50 inches annually can use lighter-duty equipment. Regions with over 100 inches need robust two-stage or three-stage models designed for heavy use.

Snow type affects equipment choice too. Coastal areas with wet, heavy snow require more powerful machines than inland regions with dry, powdery snow. The moisture content can triple snow weight, demanding significantly more power to move.

Paved driveways allow any snowblower type. The smooth surface permits single-stage models with ground-contacting augers and provides good traction for wheeled units.

Gravel driveways require two-stage models since their suspended augers won’t throw rocks. Skid shoes need careful adjustment to clear snow without disturbing the gravel surface.

Steep slopes demand self-propelled models with excellent traction. Track-drive units excel here, though wheeled models with chains can work. The engine must have sufficient power to climb while clearing snow.

Storage space often limits choices. Single-stage models fold flat for wall hanging, while two-stage units need floor space. Measure your storage area including door widths before purchasing.

Physical capability matters for non-self-propelled models. Single-stage snowblowers require pushing through snow, demanding more effort than self-propelled alternatives. Consider who will operate the equipment when choosing.

Maintenance ability affects long-term satisfaction. Gas models require more maintenance skill than electric alternatives. If you’re uncomfortable with engine maintenance, electric models offer simpler operation.

Snow removal technology continues evolving with advances in robotics, battery technology, and artificial intelligence. These developments promise easier, more efficient snow management.

Autonomous snowblowers are already in development, using GPS and sensors to clear driveways without human operation. These machines detect snowfall and automatically begin clearing when accumulation reaches preset levels.

Current prototypes use similar technology to robotic lawn mowers, with boundary wires defining work areas. Obstacles sensors prevent collisions while GPS ensures complete coverage. Commercial models should arrive within 5 years.

The challenges include handling varying snow conditions and ensuring safety around people and pets. Manufacturers are developing sophisticated sensors and AI systems to address these concerns.

Hydrogen fuel cells offer potential for zero-emission operation with quick refueling. Several manufacturers are testing fuel cell prototypes that provide gas-engine power levels with only water vapor emissions.

Solar-charged battery systems could provide sustainable power for electric snowblowers. Integrated solar panels on garage roofs could charge snowblower batteries year-round, ensuring ready power when needed.

Hybrid gas-electric systems combine benefits of both power sources. The gas engine charges batteries during operation, providing electric power for quiet early-morning clearing while maintaining gas-engine capability for heavy snow.

Understanding how your snowblower works transforms it from a mysterious machine into a logical system of interconnected components. Whether you’re operating a simple single-stage unit or a sophisticated three-stage machine, the fundamental principles remain consistent: collect, process, and discharge snow efficiently.

Regular maintenance and proper operation based on this knowledge will keep your snowblower running reliably for many winters. As technology advances, we’re seeing more environmentally friendly options that maintain or exceed the performance of traditional gas models.

The next time you fire up your snowblower to tackle winter’s worst, you’ll understand exactly what’s happening inside that hardworking machine. This knowledge helps you operate more effectively, maintain properly, and choose wisely when it’s time for replacement. Stay warm, stay safe, and let your snowblower do the heavy lifting this winter.

Don't let aphids, slugs, and caterpillars ruin another plant. Take back control with simple, natural methods that actually work.