Moving day arrives, and as you load your portable air conditioner into the truck, it tips over onto its side. Your heart sinks as you wonder: have you just destroyed your cooling lifeline?

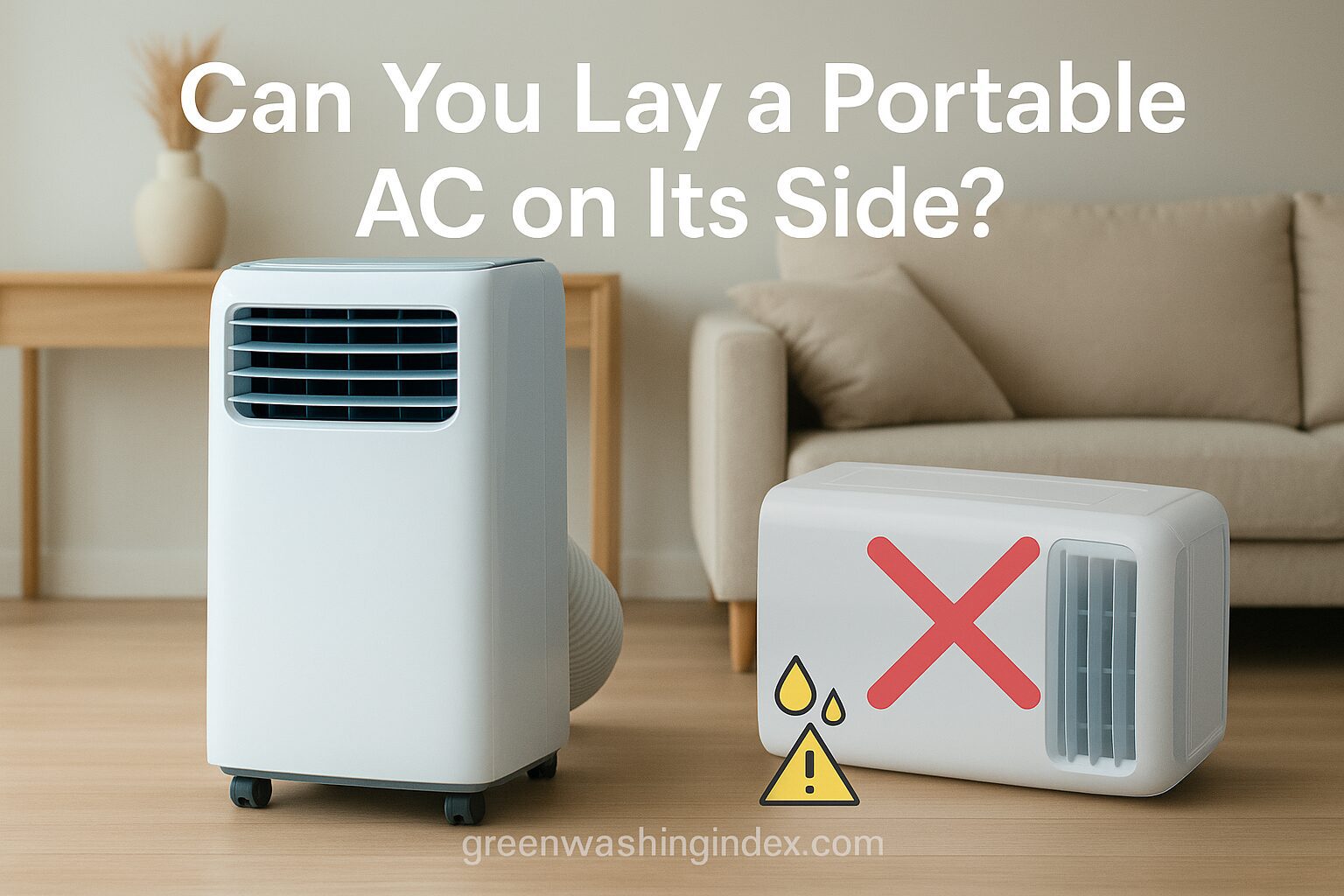

Many people face uncertainty about portable AC positioning during transport or storage, unsure whether these units can handle being laid sideways. The answer is clear: No, you should never lay a portable AC on its side. This positioning causes immediate oil migration within the compressor that can lead to permanent damage and complete system failure.

This comprehensive guide covers why side positioning is dangerous, what happens internally when an AC tips over, proper transport methods to keep your unit safe, and emergency recovery steps if your AC has already been laid sideways.

Your portable air conditioner relies on precise internal engineering to function properly. When positioned on its side, several critical systems fail simultaneously, creating a cascade of potential damage that can render your unit inoperable.

The compressor serves as the heart of your portable AC, pumping refrigerant through the system to create cooling. Inside this component, specialized oil lubricates moving parts during operation. When you lay the unit sideways, this oil immediately flows away from where it’s needed.

Within minutes of side positioning, compressor oil pools in the wrong chambers. This migration leaves critical components dry and unprotected. When the unit runs without proper lubrication, metal parts grind against each other, creating irreversible wear and potential seizure.

Refrigerants must flow in a specific pattern through your portable AC’s sealed system. Side positioning disrupts this carefully designed flow path, causing refrigerant to accumulate in unintended areas.

The liquid refrigerant can flood back into the compressor, a condition called “liquid slugging.” Since compressors can only compress gas, not liquid, this scenario often results in immediate mechanical failure when the unit starts.

Portable AC units contain precisely aligned components including fans, coils, and drainage systems. These parts rely on gravity and specific orientation to function correctly. Side positioning can cause:

Even brief periods on their side can misalign these sensitive components beyond self-correction.

Understanding the specific damage mechanisms helps illustrate why side positioning proves so destructive to portable AC units. Each affected component plays a crucial role in cooling performance.

When compressor oil migrates away from bearing surfaces, unlubricated parts begin making metal-to-metal contact. This contact generates excessive heat and metal shavings that contaminate the entire refrigerant system.

The compressor’s internal components, including pistons, connecting rods, and crankshafts, rely on precise oil film thickness. Without this protective layer, these parts collide with forces they weren’t designed to withstand. Damage often occurs within seconds of startup if oil hasn’t returned to proper locations.

Your portable AC’s evaporator and condenser coils feature delicate aluminum fins spaced precisely for optimal airflow. Side positioning places unusual weight stress on these fins, causing them to bend or collapse.

Deformed coil fins restrict airflow, reducing cooling capacity by up to 40%. Unlike simple dust buildup, bent fins require professional straightening or coil replacement. The cost for coil repair often exceeds $300, making prevention crucial.

The filter drier removes moisture and contaminants from your AC’s refrigerant system. This component contains desiccant material that must remain in specific positions to function properly.

Side positioning causes desiccant beads to shift and compact, creating blockages. A jammed filter drier restricts refrigerant flow, causing poor cooling performance and increased system pressure. Replacement typically costs $150-250 plus labor.

Portable AC units collect significant moisture during operation—up to 2 gallons daily in humid conditions. This water normally drains through designated channels to an internal tank or continuous drain.

When laid sideways, collected water flows into unintended areas including:

Water damage often appears days later as corrosion, short circuits, or mold growth inside the unit.

Potential Repair Costs from Side Positioning:

| Component Damaged | Typical Repair Cost | Replacement Cost |

| Compressor | $400-600 | $800-1200 |

| Cooling Coils | $250-350 | $400-600 |

| Filter Drier | $150-250 | $200-300 |

| Control Board | $200-300 | $350-500 |

| Fan Motor | $150-200 | $250-350 |

If your portable AC has been positioned sideways, proper recovery time becomes critical before attempting operation. The waiting period allows internal fluids to return to their correct locations.

Major manufacturers including GE recommend waiting 24 hours after a portable AC returns to upright position before powering on. This guideline provides maximum safety margin for oil return and refrigerant settling.

The 24-hour period accounts for:

While 24 hours may seem excessive, this wait time significantly reduces the risk of catastrophic compressor failure on startup.

Not all side-positioning events require the full 24-hour wait. Use these guidelines based on how long your unit remained sideways:

Less than 1 minute: Wait at least 30 minutes upright 1-10 minutes: Wait at least 2 hours upright

10-60 minutes: Wait at least 8 hours upright 1-24 hours: Wait the full 24 hours upright More than 24 hours: Wait 24 hours minimum, consider professional inspection

Remember: these represent minimum wait times. When in doubt, waiting longer provides additional protection for your investment.

Certain damage from side positioning won’t resolve with time alone. Seek professional service if you notice:

These signs indicate physical damage requiring repair before safe operation.

Proper transport technique prevents the costly damage associated with side positioning. Follow this systematic approach for safe portable AC moving.

Before moving your portable AC, complete these essential preparations:

Drain all water: Run the unit in fan-only mode for 2 hours before transport to evaporate residual moisture. Empty the water tank completely and wipe dry.

Secure loose parts: Remove and pack separately:

Document condition: Photograph the unit from multiple angles to record pre-transport condition for insurance purposes.

Clean thoroughly: Remove dust and debris that could shift during transport and clog internal components.

Position your portable AC correctly within your vehicle:

Ideal locations:

Never place the unit:

Properly secure your portable AC using these methods:

Ratchet straps: Thread straps through built-in handles or around the unit body, anchoring to vehicle tie-down points. Avoid over-tightening which can crack plastic.

Moving blankets: Wrap the unit completely, then secure with straps. Blankets provide cushioning against vibration and impact.

Bracing materials: Use foam blocks, rolled towels, or inflatable dunnage bags to fill gaps around the unit, preventing movement.

Wooden frame: For frequent transport, build a simple wooden frame that holds the unit upright and attaches to vehicle anchor points.

After reaching your destination, inspect thoroughly before use:

Vehicle-Specific Loading Tips:

Long-term storage requires the same upright positioning as transport, plus additional considerations for component preservation.

Proper winter storage extends your portable AC’s lifespan and ensures reliable operation next season:

Climate control: Store in areas maintaining 50-90°F temperatures. Extreme cold can damage seals and plastic components.

Moisture prevention: Run the unit in fan mode for 4 hours before storage to thoroughly dry internal components. Place moisture-absorbing packets inside the exhaust port.

Pest protection: Cover intake and exhaust ports with fine mesh to prevent insect or rodent entry. Avoid plastic bags that trap moisture.

Monthly rotation: If possible, run the unit for 10 minutes monthly during storage to circulate oil and prevent seal drying.

Maximize storage space while maintaining proper positioning:

Wall-mounted brackets: Install heavy-duty shelf brackets to support the unit 12 inches off the floor, improving air circulation and preventing moisture damage.

Rolling platforms: Build or purchase furniture dollies that keep units mobile while stored upright. Add walls to prevent tipping.

Closet organizers: Dedicate a coat closet section with reinforced flooring to support the unit’s 50-80 pound weight.

Vertical storage racks: Commercial wire shelving units accommodate multiple portable ACs when properly reinforced.

Climate-controlled advantages:

Garage storage considerations:

When garage storage is unavoidable, elevate units off concrete floors and cover with breathable fabric.

Pro-Tip: DIY Storage Stand Instructions

Build a custom storage stand for $30:

Materials needed:

Assembly:

Despite best efforts, accidents happen. If your portable AC tips over, immediate correct action minimizes potential damage.

First 60 seconds:

After uprighting:

After the appropriate waiting period, conduct this inspection:

Visual inspection:

Physical checks:

These symptoms indicate damage despite proper waiting:

During startup:

During operation:

Contact HVAC service immediately for:

Professional inspection costs $75-150 but prevents potentially catastrophic damage from continued operation.

Beyond side positioning, several handling errors frequently damage portable ACs during relocation.

The flexible exhaust hose seems like a convenient grip, but it connects to delicate internal components. Lifting by the hose can:

Always use designated handles or lift from the base unit.

Portable AC tops aren’t designed for weight bearing. Stacking boxes or luggage on top causes:

The unit should remain the topmost item during transport.

Each portable AC model has specific weight distribution. Ignoring center-of-gravity markings leads to:

Reference your manual for proper lifting points and balance requirements.

Impatience after tipping events causes preventable damage. Starting too soon results in:

The few hours saved never justify the risk of $500+ repairs.

No, laying a portable AC on its back causes identical problems to side positioning. The compressor oil migrates, refrigerant accumulates incorrectly, and water can leak into electrical components. Always maintain upright positioning regardless of which surface would contact the ground.

Portable ACs should remain within 5 degrees of vertical during transport. Brief angles up to 15 degrees during loading are acceptable if immediately corrected. Any position beyond 15 degrees risks oil migration and component damage. When navigating ramps or inclines, move slowly and maintain upright orientation.

Yes, all portable AC brands require upright positioning due to similar internal designs. Whether LG, Frigidaire, Honeywell, or other manufacturers, the compressor and refrigerant systems function identically. Some industrial units may have special transport positions, but all consumer models need upright storage and transport.

Most manufacturer warranties become void if units sustain damage from improper positioning. Warranty terms typically specify “proper handling and installation” requirements. Compressor damage from side positioning is easily identified during service inspection. Document proper handling during transport to protect warranty coverage.

Extended sideways storage often causes permanent damage beyond recovery. Months of improper positioning can result in:

Professional evaluation is essential before attempting operation after long-term improper storage.

Portable air conditioners must never lay on their side due to the immediate risk of compressor oil migration, refrigerant displacement, and component damage. Always transport these units in an upright position using proper securing methods, and wait the full 24 hours if tipping occurs accidentally.

Following these guidelines protects your investment and ensures reliable cooling performance for years. Save this comprehensive guide for reference during your next move, and share it with others planning to transport portable AC units. Your careful handling today prevents costly repairs tomorrow.